Biogas from biological wastes tops renewable energies as it also prevents carbon emissions and environmental pollution. It is at the heart of a burgeoning eco-economy in China, but certain constraints need to be addressed for its full potential to be realized. Prof. Li Kangmin and Dr. Mae-Wan Ho

Biogas is a combustible mixture of gases produced by micro-organisms when livestock manure and other biological wastes are allowed to ferment in the absence of air in closed containers [1] (Dream Farms). The major constituents of biogas are methane (CH4, 60 percent or more by volume) and carbon dioxide (CO2, about 35 percent); but small amounts of water vapour, hydrogen sulphide (H2S), carbon monoxide (CO), and nitrogen (N2) are also present. The composition of biogas varies according to the biological material. The methane content of biogas produced from night soil (human excreta), chicken manure and wastewater from slaughterhouse sometimes could reach 70 percent or more, while that from stalk and straw of crops is about 55 percent. The concentration of H2S in biogas produced from chicken manure and molasses could be as high as 4 000mg/m3, and from alcohol wastewater even higher at 10 000 mg/m3. Biogas is mainly used as fuel, like natural gas, while the digested mixture of liquids and solids ‘bio-slurry’ and ‘bio-sludge’ are mainly used as organic fertiliser for crops. But there are numerous other uses for biogas, bio-slurry and bio-sludge in China.

There’s evidence that biogas was used to heat bath water in Assyria during 10 BC; and the first digestion plant to produce biogas from wastes was built in a leper colony in Bombay India in 1859 [2] (Sustainable Food System for Sustainable Development).

China is one of countries in the world to have used biogas technology early in its history. By the end of the nineteenth century, simple biogas digesters had appeared in the coastal areas of southern China. Mr. Luo Guorui invented and built an eight cubic metre Guorui biogas tank in 1920, and established the Santou Guorui Biogas Lamp Company. In 1932, he moved the Company to Shanghai and changed his firm’s name to Chinese Guorui Biogas Company with many branches along the Yangtze River and in the southern provinces. Chinese Guorui Biogas Digester Practical Lecture Notes was published in 1935 [3], the first monograph on biogas in China and in the world. That was the first wave of biogas use in China.

The second wave of biogas use in China originated in Wuchang in 1958 in a campaign to exploit the multiple functions of biogas production, which simultaneously solved the problems of the disposal of manure and improvement of hygiene.

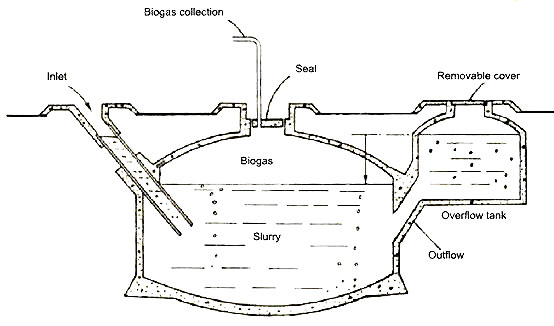

The third wave of biogas use occurred between the late 1970s and early 1980s when the Chinese government considered biogas production an effective and rational use of natural resources in rural areas. Biogas production not only provided energy, but also environmental protection and improvement of hygiene, and was an important aspect of modernization of agriculture. Some 6 million digesters were set up in China, which became the biogas capitol of the world, attracting many from the developing countries to learn from it. The ‘China dome’ digester became the standard construction to the present day (Fig. 1) [4], especially for small-scale domestic use. But many new types of rural household digesters have also been built based on water pressure, as for example, the plug flow auto-cycle rural digester, the up-flow small scale digester, the fender digester, and recently, the pulse flow anaerobic reactor.

Figure 1. China dome digester

China’s 2003-2010 National Rural Biogas Construction Plan was announced in 2003. The proposal was to increase biogas use by 11 million to a total of 20 millions households by 2005, to make one in ten farmer’s households a biogas user; although the rate would reach 15 percent in some areas. By 2010, China would increase biogas-using households by a further 31 million to a total of 50 million, so the rate of use would reach 35 percent. From 2003, a government subsidy of 1 000 Yuan (about US$ 150) would be provided for each biogas digester.

The main reason for using anaerobic digestion, which generates biogas as a by-product, is to treat wastes. According to the government’s Chinese Ecological White Paper issued in 2002 [5], the total amount of livestock and poultry wastes generated in the country reached 2.485 billion tonnes in 1995, some 3.9 times the total industrial solid wastes. These wastes are precious resources if used properly, but constitute major pollution when discharged into rivers and lakes. It is estimated that less than 10 percent of the wastewater in China is currently treated, and that 10 million ha of farmland are seriously polluted by organic wastewater and solid wastes as well.

According to the Chinese Academy of Sciences Geography and Resources China Natural Resources and Environment Data Bank, the total annual production of manure and night soil could theoretically generate about 130 billion m3 of methane, equivalent to 93 million tonnes of coal [6]. While only 50 percent of the theoretical production can be realised in rural areas, 80 percent of the industrial wastewater can also be used to produce methane.

The COD (chemical oxygen demand, a measure of pollutant concentration) of wastewater from a distiller often reaches 40 000 mg/litre while aerobic treatment only permits COD below 1 000 mg/litre, which means having to dilute the wastewater 40 times. With anaerobic digestion, 90 percent of the pollutants can be readily removed, thereby greatly reducing pollution to farmland, rivers and lakes [3].

During the 10th Five Year Plan, the government invested 35 billion Yuan to promote an ecological model based on biogas. It devoted great effort to develop 2 200 biogas engineering projects for wastes from intensive animal husbandry and poultry treating more than 60 million tonnes of manure a year. In addition, it installed 137 000 digesters to treat sewage [7].

The second main reason for anaerobic digestion is that methane is a major greenhouse gas, second to carbon dioxide in amount generated, but with a global warming potential 22 times that of carbon dioxide. Using biogas not only removes polluting wastes, but also mitigates global warming [8] (Dream Farm 2 - Story So Far). The methane flux from exposed slurry is 3.92 mg per square metre per hour, compared with 10.26 mg per square metre per hour from compost in rice fields [3]. Methane mitigation saves carbon emissions and can be traded as carbon credits under the Clean Development Mechanism of the Kyoto Protocol for climate change [9] (Biogas Bonanza for Third World Development ).

Using biogas also solves the most serious problem of energy supply in rural areas, where people traditionally forage for fuel wood in forest. A 10m3 digester in rural areas can save 2 000 kg of fuel wood, which is equivalent to reforesting 0.26-4 ha [6]. Africa lost 64 million ha of forest between 1990 and 2005, more than any other continent, and fuel wood gathering was a major cause of forest depletion [10].

Biogas methane provides fuel for cooking, not only saving the forests and also the women fetching and carrying heavy loads of fuel wood. Unlike firewood, biogas burns without smoke, thus also saving women and children from respiratory distress and disease [9]. Biogas can be used to generate electricity, prolonging the active hours of the day and enabling the family to engage in social or self-improvement activities or to earn extra income.

The anaerobic digester solves sanitation problems by taking in human as well as animal manure, improving home and farm hygiene and the general environmental conditions.

Finally, anaerobic digestion not only yields biogas but also bio-slurry and bio-dregs rich in nutrients, minerals and biologically active compounds that form excellent organic fertiliser for crops and fodder for pig and fish (see below).

The liquid and solids in the digester is a treasure trove of valuable biological resources [3]. These include major nutrients for crops such as nitrogen (N), phosphorus (P) and potassium (K), as well as trace elements that can stimulate seed germination and growth. Also present are biologically active compounds such amino acids, growth hormones, gibberelin, sugars, humic acid, unsaturated fatty acids, vitamins, cellulase and other enzymes, and antibiotics that may suppress the growth of pathogens, which benefit both plants and animals. The slurry and solids can be used as fodder for livestock and fish. The solid phase will include the micro-organisms responsible for fermenting the wastes and producing methane, which would have multiplied in the digest, constituting a rich source of protein when the digested slurry or dregs are used as fodder.

The digested slurry can be used as organic manure in the sowing season and as a source of water in other seasons. Seeds submerged in slurry germinate better and the seedlings grow stronger. Used as a spray for plants, the slurry inhibits disease and boosts yields.

The digested slurry can be used to feed fish, the dosage depending on the transparency of the fishpond (an indication of how much organic nutrient is present). It can also be fed to pigs as an additive to speed up growth and shorter the rearing period by 25 percent, saving feeds by 15 percent. When fed to boiler and layers, the slurry from cow, chicken and pig manure increased the rate of egg laying by 14 percent, 9 percent and 7 percent respectively.

The solid dregs from the digester have high levels of humic acid and can be used as a soil conditioner or as substrate for culturing mushrooms. They can also be used to culture earthworms to be fed to chickens. Chickens fed earthworms lay 15 to 30 percent more eggs [11].

Biogas can be used directly for cooking and for co-generation of electricity and heat, which is especially feasible when the biogas is used at or near the site of generation.

Biogas methane can also be used as fuel for vehicles, and is the cleanest biofuel available. Cars run on biogas methane have been voted environmental cars of the year in 2005. Thousands of them are already operating in Sweden, which has hundreds of filling stations supplied by community biogas digesters [12] (Organic Waste-Powered Cars).

Biogas can be used in ovens and lamps to heat greenhouses and at the same time increase the carbon dioxide concentration to boost photosynthesis in the greenhouse plants and increase yields. Experiments in Shanxi Province have shown that increasing carbon dioxide four-fold between 6 and 8 am boosts yields by 67.2 percent [3]. Similarly, a biogas lamp gives both light and warmth to silkworm eggs increasing their rate of hatching as well as cocooning over the usual coal heating [3].

Biogas methane can also be used to make methanol, an organic solvent and important chemical for producing formaldehyde, chloromethane, organic glass, and compound fibre [13].

Finally, biogas can be used to prolong storage of fruit and grain [3]. An atmosphere of methane and carbon dioxide inhibits metabolism, thereby reducing the formation of ethylene in fruits and grains. It also kills harmful insects, mould, and bacteria that cause diseases.

In 1996, grain production reached 504.3 million tonnes in China. It was hard to sell the grains. Nanyang in Henan Province had 6.7 million ha of wheat crop (1 percent of wheat cropland in China), and a record yield of 9.5 tonnes/ha that year. Nanyang also had 1.5 million tonnes of shop worn grains. So, Tianguan Alcohol Factory expanded its operation to consume 1.75 million tonnes of shop worn grains/year to produce denatured alcohol as fuel for automobiles, and used the dregs of the distiller to produce biogas in a 30 000 m3 digester, supplying more than 20 000 households or 20 percent of the population. Nanyang became a biogas city in China.

Meili village of Shaoxing Country, Zhejiang Province produces 28 000 pigs, 10 000 ducks, 1 million ducklings and 100 000 chickens each year. In 2001, they spent 1.2 million Yuan to build digesters to treat 30 tonnes of livestock and poultry wastes and nightsoil. This produced enough biogas for more than 300 households plus 7 200 tonnes of organic fertilizer each year.

Hongzhi Alcohol Corporation Limited located in Mianzhu in Sichuan Province is the largest alcohol factory in south-western China, and produces alcohol for human consumption. It runs a service using industrial organic wastewater, sewage and dregs to produce biogas, paid for by industry and residents in cities, but provided free to farmers. The company also built a biogas power plant generating 7 million kilowatts per hour. The city of Mianzhu treats 98 percent of municipal sewage including wastewater from hospitals through digesters with a total capacity of 10 000 m3. The treated water reached national discharge standards, greatly improving the environment.

Up to the end of 2005, China has 17 million digesters with annual production of 6.5 billion m3 biogas [15], mostly in rural areas, with 50 million people enjoying the benefits of biogas technology. The annual production of biogas is projected to reach 25 billion m3 by 2020. Biogas could provide energy to one quarter of households in rural areas.

Biogas is at the centre of a burgeoning eco-economy in China. As animal husbandry goes intensive, there are many large or medium size livestock and poultry farms in the suburbs of cities. An example is Fushan farm in Hangzhou, with 32.47 ha paddy fields, 4 ha tea trees, 13.7 ha water shields and 7.3 ha fishponds. It also produces 30 000 laying hens, 150 000 broilers, and 8 000 pigs a year, with 15 tonnes of solid waste and 70 tonnes of wastewater discharged daily, a huge amount of pollution. But using biogas digesters to deal with the pig and poultry wastes, biogas energy becomes available for processing tea and heating the chicken coop, and there’s fodder for fish and pigs and fertilisers for tea trees and the paddy fields, and no pollution is exported to surrounding areas [7]. This eco-farm has now moved to the outskirts far from the city because of its malodour, however. It is possible to use a combination of multiple micro-organisms to deodorize pig manure or chicken manure. Also, the large amounts of water in slurry could be reused to wash away wastes in hog houses as a water-saving measure.

Northern China has cold winters but sufficient sunshine. Digesters do not operate below 10 C, and pigs raised in winter eat but do not fatten. People also lack fresh vegetables in winter. All these problems are solved with a four-in-one eco-model that provides a greenhouse to plant vegetables, a shed to raise pigs, a digester underneath the pig shed and a toilet in the big green house adjoining the pig shed [3]. The pigs grow well with manure flowing into the digester together with human excreta. The digester works well because the temperature could be kept above 10 C, and it greatly improves the living conditions of farmers. The digester provides biogas as energy, slurry and dregs as fertilisers, and the pigs produce carbon dioxide to enrich the greenhouse to produce plenty of quality vegetables.

In southern China, a five-in-one model incorporates pigs, digester, fruit orchard, light trap, and fishponds [3]. The pig manure flows into a digester to be fermented. Biogas is harvested to provide energy for cooking and lighting. The digested slurry is used as fertilizer for the fruit gardens and feed for pig and fish. The light-trap hangs above the fishpond to attract and kill pests, which become additional fish feed. This model is practised especially in Guangxi Province in southern China, where a yellow sticky board (a kind of fly paper) is hung in the orchard for additional pest control [16].

China is building new socialist villages in its current 11th five-year plan. The guidelines are to develop production and to clean the environment, to innovate to save resources. Developing biogas fits in well with this programme. The major constraint is the lack of technical capacity for running and maintaining the biogas digester.

However, a new breed of biogas farmer workers has appeared. For example, Mr. Liu Zijian in Guangxi Province is playing a major role in his village. Liu first built an eight cubic metre digester and renovated the toilet, pigsty and kitchen at the same time, saving 7 540 Yuan (~US$ 1 000). He has worked out effective ways of getting the digester to start producing methane, and how to ensure success. Indeed, he has built 130 digesters without a single failure. The whole village has 165 digesters serving 72 percent of villagers. Nevertheless, any improvement in the design of biogas digesters to make installation and maintenance easier will encourage wider uptake. Up to the end of 2005, Shanxi Province held 40 biogas technical training courses and trained 6 000 farmers, 4 037 of which gained National Biogas Professional Technician Certificate [17]. In order to popularise the biogas technology, a training course is held twice a month lasting 7 days and costing 600 Yuan per person (280 Yuan by correspondence). After completing the course, participants would be given a professional technical grade certificate that is recognized by the state [18].

The Pearl River Delta in Guangdong Province is famous for its dyke-pond system, which integrates fish farming with crops cultivated on the dykes between fishponds. Here, the uptake of biogas digesters is poor, at least partly because when electrification arrived, according to Prof. Deng Hanzeng of Guangzhou Institute of Geography, it was just much easier to operate the switch rather than maintain a digester. Prof. Deng was part of a team of scientist led by Prof. Zhong Gongfu who, in the 1980s, pioneered the study of the dyke-pond system developed by farmers in the Pearl River Delta and elsewhere over the past two thousand years [19]. They would very much like to see biogas digesters and other sustainable, zero-emission and zero-waste practices revitalised and adopted in the region.

Another important factor to encourage widespread adoption of biogas technology is an appropriate legal framework. For example, a comprehensive ecological tax reform law came into effect in Germany in March 1999 that raised taxes on energy sources tied to carbon emissions, and exempted renewables from taxation. In February 2000, the German parliament passed a Renewable Energies Sources Act that included payments for excess green energy generation fed back into the power grid [20]. In that event, the meters run backwards, reducing the customer’s electricity bills. These policies help make green energy cost-effective, and are essential to the ultimate success of green power programmes.

To maximise the benefits of biogas as energy, China also needs advanced technologies to purify and compress methane and to build new engines that use methane effectively and efficiently [12], to run cars as well as farm machinery.

The prospects for biogas as renewable energy are excellent, provided the constraints can be removed. Anaerobic digesters can also treat crop and food wastes as well as the algal blooms and water hyacinths that clog up polluted rivers and turn them into biogas energy.

Li Kangmin is Professor of Asian Pacific Regional Research and Training Centre for Integrated Fish Farming, and China’s representation on the International Organization of Biotechnology and Bio-engineering. He teaches integrated fish farming and has researched and published extensively on ecological agriculture and local circular economy, including eutrophication control, surface aquaponics, vermiculture and biogas development.

Article first published 02/10/06

Got something to say about this page? Comment