Flexible high density charge storage graphene micro-supercapacitors made with home DVD laser burner in less than 30 min, far out-perform commercially available product and herald in the next miniaturization revolution Dr. Mae-Wan Ho

The rapid miniaturization of electronic devices is limited by the lack of compact on-chip energy storage to complement or replace batteries. Carbon is a clear favourite in terms of material for making micro-supercapacitors that could fit the bill, especially the 2-dimensional single atomic layer carbon crystal grahene, whose remarkable electronic and other properties have been arousing a frenzy of excitement for nearly a decade (see [1] Graphene & New Age of Carbon, SiS 59). Two chemists at the University of California Los Angeles, Maher Elkady and Richard Kaner, have produced an impressive prototype array of graphene micro-supercapacitors using little more than a home-version DVD laser burner (see Figure 1). They also found that miniaturizing the device to micron scale results in enhanced charge-storage capacity and performance, giving a power density of ~200 W cm-3, among the highest achieved for any supercapacitor. The process is readily scalable and the devices can be made on large substrates at a fraction of the cost of traditional microfabrication methods. The devices are printed on a flexible substrate for flexible electronics and can be integrated with microelectrochemical mechanical systems or complementary metal oxide semiconductors on a single chip [2].

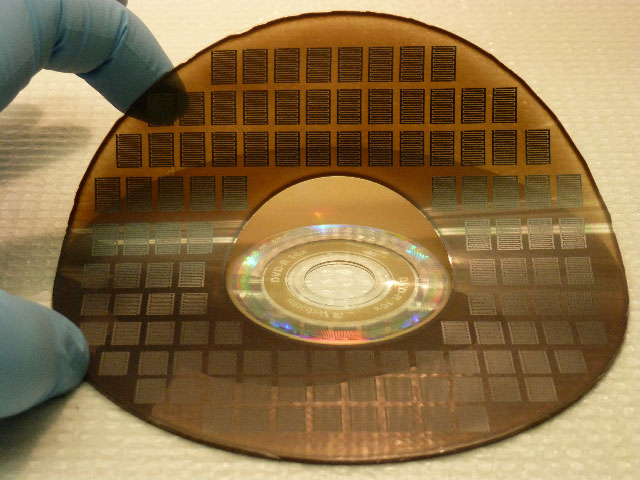

Figure 1 An array of more than 100 micro-supercapacitors fabricated on a flexible disc the size of a DVD using a home DVD laser burner

The real genius in the work is in using inexpensive everyday technology and materials, as Elkady, a graduate student and lead author of the report explained [3]: “Traditional methods for the fabrication of micro-supercapacitors involve labour-intensive lithographic techniques that have proven difficult for building cost-effective devices, thus limiting their commercial application. Instead, we used a consumer-grade LightScribe DVD burner to produce graphene micro-supercapacitors over large areas at a fraction of the cost of traditional devices. Using this technique, we have been able to produce more than 100 micro-supercapacitors on a single disc in less than 30 minutes, using inexpensive materials.”

El-Kady and his supervisor Kaner also used a new design. Instead of stacked layers of graphene serving as electrodes like a sandwich, they etched the electrodes side by side in an interdigitated pattern. This maximizes the accessible surface area available for each of the two electrodes while also reducing the path the charged ions in the electrolyte need to diffuse. As a result, the new supercapacitors have more charge capacity as well as rate capability than the stacked counterparts. Interestingly, the researchers found that by placing more electrodes per unit area, they boosted the micro-supercapacitor’s ability to store even more charge.

To make the micro-supercapacitors according to the designed pattern, they glued a layer of plastic onto the surface of a DVD and coated the plastic with a layer of graphite oxide bought off the shelf. Then they simply inserted the coated disc into the commercially available optical drive used to label DVDs, and took advantage of the drive’s own laser to create the interdigitated pattern. The laser scribing was so precise that none of the interwoven fingers of the two electrodes touched each other, up to one with 16 microelectrodes (8 positive and 8 negative). This was important; otherwise it would short-circuit the capacitor. The unburnt graphene oxide (brown areas) conveniently is an insulator, while the graphene (black areas) acts as both electrode and current collector (Figure 2).

Figure 2 An array of three microcapacitors with (left to right) 4, 8 and 16 interdigitated electrodes on a flexible substrate

The laser-action was simple. Kaner and El-Kady previously found that graphene oxide, when exposed to light is converted into graphene, which is similar to what happens in using

LightScribe to label DVDs, the surface of the disc is coated with a reactive dye that changes colour on exposure to the laser light. So, the drive burns the computer-designed pattern onto the graphite oxide film to produce the desired graphene circuits.

In a comprehensive series of tests [2], the researchers showed that their new micro-supercapacitors outperform both a sandwiched type microcapacitor as well as a commercial microcapacitor in storage capacity and charging/discharging times. The micro-supercapacitors also exhibited excellent cycling stability, losing only 4 % of its initial capacitance over 10 000 cycles of charging and discharging. This give it an important advantage over micro-batteries that have shorter lifespans and could pose a major problem when embedded in permanent structures such as biomedical implants, active radio-frequency identification tags and embedded micro-sensors, for which no maintenance or replacement is possible.

An important quality measure of a capacitor is the RC time constant (in seconds), equal to the product of the circuit resistance (in ohms) and the circuit capacitance (in farads), and is the time required to charge or discharge the capacitor, through the resistor by ≈ 63.2 % of the difference between the initial value and final value. The RC time constant of the device with 16 electrodes was 19 ms, compared with 10 s for the commercial activated carbon supercapacitor and 1.1 ms for an aluminium electrolytic capacitor.

The new micro-supercapacitors are highly bendable and twistable. When tested under constant strain, they showed exceptional stability regardless of the degree of bending or twisting. The capacitance was reversibly maintained with 97 % retention of the initial capacitance after 2 000 cycles. This makes them potentially useful as energy-storage devices in flexible electronics like roll-up displays and TVs, e-paper, and even wearable electronics. (How about clothing that harvest ambient, or your own body energy to cool you in summer and warm you in winter?)

The researchers created the micro-supercapacitor in an all-solid form by using an ionogel electrotyle created by mixing together fumed silica nanopowder with the ionic liquid 1-butyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide. This gave rise to all solid-state micro-supercapacitors that can be operated at a larger potential window of 2.5V compared with the 1 V of the best currently available. The solid state enables the micro-supercapacitors to be more easily shaped for incorporating into any new device, or they could be fabricated directly onto a chip for integration into micro-electromechanical systems (MEMS) and complementary metal-oxide-semiconductors (CMOS). This may help to better extract energy from solar, mechanical and thermal sources and make more efficient self-powered systems. The solid-state micro-supercapacitors could be fabricated on the backside of solar cells in both portable devices and rooftop installations to store power generated during the day for use after sundown, and provide electricity, potentially around the clock without connecting to the grid.

This is only the beginning, the possibilities are endless.

Article first published 08/07/13

Got something to say about this page? Comment

There are 2 comments on this article so far. Add your comment above.

Rory Short Comment left 23rd July 2013 06:06:11

These kind of developments excite and amaze me. I always hope that they are rapidly taken up despite the resistance from the inevitable vested interests of various kinds.

Thomas Blakeslee Comment left 12th September 2013 14:02:05

This is a really exciting breakthrough! The work was sponsored by Maxwell Technologies MXWL. They are the leader in ultracapacitors for cars and busses. Let's hope they commercialize this quickly. The world needs it.