Solar Power

Solar power is poised to enter the mainstream energy market with novel materials that boost energy conversion efficiency and bring down manufacturing costs. Dr. Mae-Wan Ho

The ability of sunlight to generate electricity was first discovered by French physicist Andre-Edmond Becquerel in 1839, when he observed that shining light on certain materials produced an electric current. But it took just over a hundred years to 1941 before Russell Ohl in the United States invented a silicon solar cell.

The silicon solar cell (Box 1) is still the predominant model in use today, representing some 94 percent of the global market. But even with energy conversion efficiencies as high as 33 percent, silicon-based solar cells are still too expensive for general use.

Box 1

The conventional solar cell

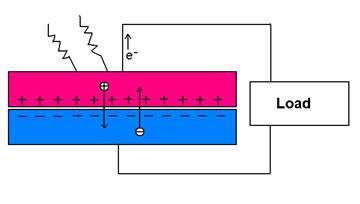

The conventional solar cell is made from inorganic crystalline semi-conducting material such as silicon, which is ‘doped’ (slightly contaminated with appropriate elements) to form a p-n junction. The p side of the junction contains an excess of positive charges (holes), the n side, an excess of negative charges (electrons). This creates an electric field across the junction.

When sunlight is absorbed in the bulk of the silicon, free electrons and holes are created, which are accelerated by the electric field to go to the appropriate electrodes on the top and bottom of the cell (see Fig. 1). On reaching the electrode, the electrons leave the device to drive the external electric load, returning to recombine with the holes at the other, counter electrode.

Figure 1. Diagram of a conventional solar cell

The conversion efficiency of the solar cell is defined as the ratio of the electric power provided to the external circuit to the solar power incident on the active area of the cell. It is typically measured under standard simulated conditions.

In recent years, fuelled by the growing global energy demands and to some extent, by the need to reduce carbon emissions to mitigate global warming, solar power is gaining in popularity as improvements in design boost energy conversion efficiency and lower manufacturing costs (see Box 2). There is a trade-off between the cost of manufacture and the efficiency, which is expressed in the unit price of electricity generated. The current cost of about $4/W is still considered too high for the market. The US Department of Energy has set a target to lower unit price to $0.33/W; but as the prices of oil and gas are both rising, solar power will begin to look much more competitive as research and development continue to improve on efficiency and cost, and especially when carbon credits from reducing carbon dioxide emissions are factored in.

A major advantage of solar power is that it has minimum impacts on the environment, which are mostly associated with the manufacturing processes, and do not require major changes in land use [1]. Solar panels can be conveniently integrated into existing building structures and rooftops; and large arrays can be sited in deserts.

Box 2

The world produces 4.6 x 1020 J per year [2], and the earth’s surface average solar energy is ~ 4 x 1024 J/year [3]. Thus, even with solar cells at a low, 10 percent conversion efficiency, the world’s energy needs can be satisfied with solar panels covering just over 0.1 percent of the earth surface.

Worldwide, photovoltaic installations increased by 927MW in 2004 [4], up from 574MW installed during the previous year. In 1985, annual solar installation demand was only 21 MW. On the supply side, 742 MW of solar panels were produced in 2003. But current cumulative solar energy production accounts for less than 0.01 percent of total global energy demand, even though it has been growing at about 25 percent per year over the past 15 years.

Japan manufactured 50 percent of the world’s solar cells in 2003; and has overtaken the US as the largest net exporter of solar cells and modules. Four companies account for over 50 percent of solar cell production: Sharp, Kyocera, BP Solar and Shell Solar. Sharp remains the largest company, and has shown the fastest growth over the past five years; Sanyo, fifth largest has shown the second highest rate of growth over the same period. Solar energy prices have declined on average 4 percent per year over the past 15 years, due to progressive increase in conversion efficiencies and manufacturing economies of scale.

But to really capture the mainstream energy market, major increases in energy conversion efficiency and/or reductions in manufacturing cost are needed; and the prospects look bright for both.

Over the past decade, “second generation” thin-film technologies have been developed that do not require costly crystalline silicon wafers and can be manufactured much more cheaply. These include devices based on a range of new inorganic semi-conducting materials, as well as multi-junction amorphous (non-crystalline) silicon. Thin-film cells are fabricated using techniques such as sputtering, physical vapour deposition and plasma-enhanced chemical vapour deposition.

Multi-junction cells based on amorphous silicon have been the most successful second-generation technology todate. Amorphous silicon can be made from waste silicon from the computer chips industry, and devices can be manufactured at relatively low cost and at high speed with roll-to-roll processing on flexible stainless steel and other substrates, which can be easily integrated into roofing materials. These advantages have helped them capture the 5.6-6 percent of the market not dominated by crystalline or polycrystalline silicon. One such product on the market is a triple-junction flexible solar panel [5] made of three separate amorphous silicon layers, each with a different bandgap, so as to harvest light from the entire solar spectrum, and works even in cloudy conditions. It has a conversion efficiency of 13 percent; and a test panel averaged nearly 70 percent of its rated maximum output during the daylight hours of a typically grey British winter (1998/9).

In May 2005, Sharp Corporation, the world’s top manufacturer of solar panels, announced the introduction of a new polycrystalline solar module in Japan with the industry’s highest conversion efficiency of 15.8 percent [6]. This sets a benchmark for all second and third generation solar cells.

Third generation technologies are based on new materials, new mechanisms and concepts in light energy harvesting and conversion. They come in two kinds: those aimed at achieving very high efficiencies and the rest aimed at the lowest cost with moderate efficiencies of 15-20 percent. In the first category are approaches based on quantum dots and new mechanisms, such as ‘hot carriers’, thermovoltaics and multiple electron-hole pair creation (“Quantum dots and ultra efficient solar cells”, this series). These are at the early research stage and yielding exciting results, but are not yet ready for the market. The second category includes a wide range of applications based on organic material, some of which are near to market, or already in market (see next article).

Article first published 17/01/06

Got something to say about this page? Comment