Anaerobic digestion is the key to China’s rural development, but much more training and technical support needed, and better yet, an integrated approach to food and renewable energy, involvement of the local community and promotion of local enterprise. Dr. Mae-Wan Ho

A revolution is happening quietly in the Chinese countryside, while the world’s attention is preoccupied with China’s phenomenal economic growth, relentless industrial expansion, the country’s widening gap between rich and poor, and accelerated environmental degradation from pressures to increase agricultural production (see [1] The Green Shoots of China and other articles in the series, SiS 46).

At the opening session of the 10th National People’s Congress in March 2006, Chinese premier Wen Jiabao spoke of the hardships of the country’s 130 million migrant workers and of poverty in rural China. The “New Socialist Countryside” programme was launched to improve the welfare of those living outside booming cities like Shenzhen, Guangzhou, Shanghai, and Beijing [2, 3]. An important part of that programme is to provide biogas for rural China.

Biogas is a combustible mixture of gases produced by micro-organisms when livestock manure and other biological wastes are allowed to ferment in the absence of air in closed containers, or anaerobic digesters. The major constituents of biogas are methane (CH4, 60 percent or more by volume) and carbon dioxide (CO2, about 35 percent); plus small amounts of water vapour, hydrogen sulphide (H2S), carbon monoxide (CO), and nitrogen (N2). The composition of biogas varies according to the biological material fed into the digester.

Biogas from organic agricultural and food wastes is widely recognized as the most sustainable renewable bioenergy. Unlike biodiesel and ethanol from crops, biogas from organic wastes does not compete for land that should be growing food ([4] Biofuels & World Hunger, SiS 49), and has many other advantages besides ([5] Sustainable Agriculture, Green Energies and the Circular Economy, SiS 46).

Biogas is a clean cooking fuel and can be used for heating and generating electricity; it is also a fuel for mobile vehicles and farm machinery. Anaerobic digestion prevents environmental pollution and conserves nutrients such as nitrogen and phosphorous for soil fertility, the residue and slurry from the digester are excellent fertilizers. Anaerobic digestion improves food and farm hygiene by removing 90 percent or more of harmful pathogens. In the context of climate change, it saves on carbon emissions twice over: by preventing the escape of methane - a strong greenhouse gas with global warming potential of 25 times the same amount of CO2 over 100 years – that at the same time, substitutes for fossil fuel use.

China is one of first countries in the world to use biogas technology; and it has been revived in successive campaigns by the current government to provide sanitation and energy, and to modernize agriculture (see [6] Biogas China, SiS 32).

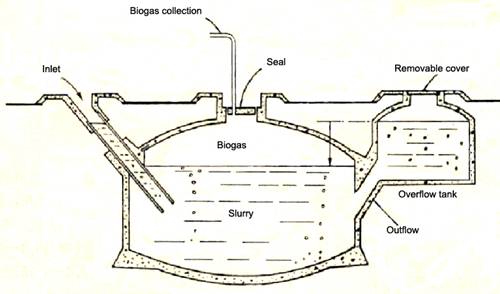

The ‘China dome’ anaerobic digester became the standard construction to the present day (Fig. 1), especially for small-scale domestic use. In 2000, commercial household biogas digesters made of glass fibre reinforced plastics entered the market [7]. This has a thickness of 5-8 mm (less than one-tenth of the traditional bricks and mortar construction); a high tensile strength of 93.5 MPa (1 atmosphere = 101 325 Pa) and a bending strength of 109 MPa. The volume range is from 6 to 10 m3. It was a major improvement; giving better insulation, a longer operational life, lower maintenance cost, and a shorter construction time of half a day instead of 10 days. It also reduced the cost slightly from 1 800 to 1 700 Yuan, and reduced the weight 40 fold to 200 kg.

Figure 1. China dome digester

The current exponential growth phase of biogas use in China began around 1995 [7]. In 2000, the Ministry of Agriculture proposed the “Biological Enrichment of the Countryside Project”; this was followed by the “Rural Household Biogas State Debt Project” in 2003 and the “Rural Biogas Project” in 2007.

By 2007, there were 26.5 million biogas plants, with a combined output of 10.5 billion m3 biogas (equivalent to 7.99 GW capacity). Household biogas digesters are found throughout the country, mainly in the Yangtze River Basin, Sichuan Province has the largest number of biogas plants, with 2.94 million running.

In 2007, 60 percent of Chinese population, or 0.9 billion live in rural areas. The per capita consumption of energy was 960 kg coal equivalent (about 28.8GJ), of which 539 kg (56 percent) was used in daily life: 32.8 percent straw, 21.2 percent fuel wood, 34.3 percent, coal, and 1.5 percent biogas. It is estimated that only 19 percent of the actual potential for biogas production has been realized.

During the 11th five-year plan (2006-2010), there has been rapid extension of biogas use in rural areas. China’s Agriculture Minister says it has become one of the most important programme in promoting people’s well-being [8]. As a result, the government simultaneously developed biogas digesters for every scale: small for households, medium and large for industrial use.

During the same period, a total of 12.78 million households installed biogas digesters with funds from the central Government. An estimated 5 042 medium and large biogas facilities will have been built by the end of 2010, representing 107 per cent of the target in the 11th 5-year plan.

The biogas industry has been growing continuously. By 2009, the number of biogas workers in the country reached 267 000, and the output value of rural biogas was 24.7 billion Yuan, four times as much as in 2005. The Agricultural Ministry concluded that “biogas application in rural areas has reaped economic, ecological and social benefits, helping improve the energy structure in rural areas, promoting the growth of ecological recycling agriculture, and improving the rural environment.”

Another benefit of biogas comes from the Clean Development Mechanism (CDM) market. China has 701 projects registered with the CDM executive board by 19 Jan 2010; mostly related to small-scale hydroelectric power, industrial energy efficiency and renewable energy development [9]. Dong Honmin, deputy director of the Institute of Environment and Sustainable Development in Agriculture, Chinese Academy of Sciences, said biogas CDM projects have great potential to control greenhouse gas emissions and increase farmers’ incomes.

Dong developed China’s first household biogas digester project in Enshi, a poverty-stricken city in Hubei province, which was approved by the CDM executive board in 2009. The project lasts for ten years and is expected to bring 60 million Yuan (~ US$9 million) to farmers; each farmer earning 182 Yuan a year from the project, she said.

However, as a biogas digester costs between 4 200 to 5 000 Yuan (US$630 to US$750), less than 20 percent of the families can afford it. Some 5 million rural household biogas digesters will be built in 2010; bringing the total number of households with biogas to 40 million by the end of the year, according to a plan announced by the Ministry of Agriculture.

At the end of 2007, household use of biogas in China was assessed by a research team at the College of Forestry, Northwest A&F University, Yangling, Shanxi Province, as the doctoral thesis of Yu Chen [7]. Biogas was installed according to several models as appropriate to different parts of the country.

The three-in-one model combines the biogas digester with a pigpen and toilet, and is popular in southern China. Biogas can be used as fuel for lighting and cooking, and the slurry as a fertilizer for growing fruit trees, vegetables and grain, and as pest control agent. By connecting the toilet to the biogas plant, the spread of disease caused by mosquito breeding can be eliminated. It also prevents infectious diseases and contamination of drinking water by human and animal manure to some extent. This model requires the least capital input and is quickly effective.

The four-in-one model adds a solar greenhouse for northern China, which increases the operating temperature of the biogas digester and the efficiency of biogas production during cold weather. Biogas can be used to heat the greenhouse for growing vegetables and fodder for the pigs. Used as a spray for vegetables, the slurry inhibits disease and boosts yields. Constructing a solar greenhouse requires a larger input of capital and growing greenhouse vegetables requires more water; consequently, this model is appropriate for regional development in the North where solar energy is abundant, the economic conditions are more favourable, and water resources are adequate.

The five-in-one model combines biogas digester with solar-powered barns, an orchard, a water-saving irrigation system, a water cellar, and toilet, and is proposed for northwest China. Biogas fertilizer is used on fruit trees to improve the quality of the fruit. Water collected in a water cellar is used in the biogas digester and for watering the orchard and irrigating other crops. The introduction of water-saving devices greatly eases the demand on water especially for the orchard. The model is suitable for regional development in the Northwest where water is in very short supply.

There are several conditions favouring China’s rural biogas programmes: firm commitment by the government and heavy government investment, the abundant availability of feedstock for anaerobic digestion, appropriate legislation, opportunities offered by CDM, and the involvement of the Asian Development Bank and other development agencies.

From 2003 to 2010, China invested a total of 61 billion Yuan in its rural biogas programmes; 15 billion from the National Investment Fund. In 2003, the Ministry of Agriculture Development and Reform commission started the Project of Rural Household Biogas State Debt and invested 840 million Yuan for constructing household biogas digesters in 22 provinces. In 2004, the programme continued to provide 1 billion Yuan of national debt. In 2005, central investment for rural biogas digester construction rose to 2.5 billion Yuan, of which 2 billion was for household digesters, and 0.5 for large and medium-sized digesters. As stipulated by the Rural Biogas construction State Debt Program Management Method, central finance subsidizes 1 200 Yuan/household in the northwestern and northeastern regions, 1 000 Yuan/household in the southwestern region and 800 Yuan/household in other regions.

There is abundant feedstock for biogas digestion in rural China, in the form of livestock and poultry manure - mostly from cattle, pigs and chicken - and agricultural residues. The total physical quantity of dry excrement resource in China at last census (2007) was 1 467 million tonnes of which 1 023 million tonnes could be collected, equivalent to 107Mt of coal (~3.1244 EJ). According to the plan for livestock industry development, livestock and poultry manure in 2010 and 2020 will reach 2.5 billion and 4 billion tonnes respectively, equivalent to 120 and 160 million tonnes of standard coal respectively (or 3.504 and 4.672 EJ respectively).

Straw is another potential feedstock for biogas production. Straw is used for papermaking (2.1 percent), forage (28 percent), rural energy resource (53.6 percent) and recycling in field (16.2 percent). There are about 681 million tonnes of agricultural residue produced annually in China, of which 546 million tonnes can be collected, and 290 million tonnes can be used for energy, equiv to 145 million tonnes of standard coal (4.234 EJ). The total amount of straw will continue to grow with population increase.

China’s Law on Renewable Energy enacted 28 February 2005 provides a strong driver for biogas development, both in increasing energy supply and in protecting the environment. The CDM, as mentioned earlier, offers additional opportunity for increasing the income of farmers through biogas production from wastes and the sale of verified carbon emission savings.

The Asian Development Bank (ADB) offered US$33.1 million in loans targeting rural Shanxi, Hubei, Henan and Jiangxi provinces in 2003 in conjunction with China’s Ministry of Agriculture (see Chapter 21 in [10] Green Energies - 100% Renewable by 2050, I-SIS Publication). The Shanxi provincial authority topped up its $8.2 with $8.1 million in matching funds and $841 000 grant from the Global Environment Fund.

Farmers received loans equivalent to half the construction costs, with repayment schedules based on the income levels and living conditions of the farmers. They were also given technical support and training to ensure that the biogas facilities are sustainable.

Through the ADB biogas projects, more than 9 000 people were trained in Shanxi, including 8 000 farmers and 300 biogas facility experts, construction workers and management staff. More than 60 percent of the trainees are women, as women are the main users of biogas for cooking and other purposes in their homes.

Xinxing Co in Jiaochen county received a US$ 200 000 ADB loan to build a new pig farm, scheduled for completion in 2010. A biogas plant will process the pig dung to produce biogas. The farm’s production capacity will increase from 2 200 pigs to about 9 000 animals. The company plans to support the energy needs of more than 300 households once the larger pig farm is fully operational. About 100 households are receiving biogas free at present. In future, the energy from the farm will be priced at 1.2 to 1.5 Yuan per m3, which is still cheaper than burning coal.

The research team at Northwest A&F University, Yangling, also identified constraints on biogas use in China associated with the need for technological improvements in anaerobic digestion, lack of training in the use of biogas, and poor follow-up services and management of biogas digesters [7].

Technologically, the fermentation of straw is limited by its low content of nitrogen and phosphorous, which hinders microbial fermentation. Also, its main components of cellulose, hemi-cellulose and lignin are slow to break down. The first limitation can be addressed by mixed digestion, which has been shown to boost efficiency greatly (see [4]). There is also ongoing research in China and elsewhere showing that brief heat pre-treatment at 170 ˚C with microwave [11] and the use of waste mushroom compost extracts containing enzymes that break down cellulose [12] can indeed improve the digestibility of straw and wood pulp wastes, and improve the yields of biogas.

Another limitation is that the minimum temperature for biogas production is 10 ˚C, and the rate goes up as temperature increases. During the winter months from November to March in northern China, temperatures drop below 10 ˚C. Hence more research is needed to improve the efficiency of biogas production in cold regions. (One way to overcome this is by flushing heated (grey) water into the biogas digester and improving the insulation.)

The lack of training among biogas users is a big problem. As a result, people are unable to combine biogas production with eco-agricultural technology. In other words, they only use the biogas for cooking and lighting, but the slurry and residue are not used as fertilizers, and hence the economic potential of biogas technology is practically untapped, while the ecological exploitation is only 4 percent.

The follow-up services and management of biogas digestion are very important for biogas development in rural China. So far, the focus has been on construction and installation, but management has been relatively neglected. Thus, a number of biogas projects have broken down. Of the 26.5 million biogas digesters installed in rural China by the end of 2007, only 60 percent were operating adequately. Biogas technology-literate staff is in short supply. Most provinces have only small rural energy offices at county-level with a handful of employees; and they find it difficult to keep up with the rapid developments in biogas technology. In addition, biogas lights, stoves and other equipment are rarely in the market, and even when available, farmers do not know how to install them.

Training in all aspects of biogas technology is obviously very important for the success of biogas use. Not mentioned in the assessment [7], but crucial, in my opinion, are involvement of the local community, the simultaneous development of small local enterprises in biogas maintenance services, manufacture of biogas stoves and other equipment that could extend to battery chargers (to store energy when biogas is in abundant supply) for mobile phone, TV and other electrical appliances.

Many of the constraints can also be addressed by taking an integrated ‘circular economy’ approach to food and energy in a ‘Dream Farm 2’ model I have proposed elsewhere (see [13] Sustainable Agriculture, Green Energies and the Circular Economy, SiS 46).

The Grameen Shakti programme in Bangladesh (see [14] Grameen Shakti for Renewable Energies, SiS 49) has certainly demonstrated the success of a concerted approach to renewable energies involving microcredit, the training of women technicians and encouraging local enterprise.

Article first published 17/11/10

Comments are now closed for this article

There are 3 comments on this article.

Vaikunthanath Kaviraj Comment left 18th November 2010 04:04:14

Dear Mae-Wan Ho, what a laudable initiative! It may be opportune to also interest the Chinese Government in the following program:

www.considera.co.uk Agrohomoeopathy, which is the use of homoeopathic remedies on food crops, grains and flowers.

It is frugal with resources, cheap to produce and gives a proven protection against pests and diseases in plants for 3 months from a single dose. It will reduce fossil fuel dependence by at least 30-50%, produce clean food coupled to larger harvests by 30%, avoid pollution with agrochemicals and give an economic boost to the agricultural population.

I have developed this over the last 25 years and am ready and willing to have my book "Homoeopathy for Farm and Garden" translated in Chinese and the products manufactured over there. I have a special formula for preparation, which can be provided against a nominal fee of 2%. Please let me know if you have any contacts I might write to enable this to eventuate.

Sincerely yours,

Kaviraj

Vice President World Homoeopathic Association, UK chapter; Classical Homoeopath, Author and Lecturer.

See also my page at http://www.homeopathyworldcommunity.com/profile/VaikunthanathdaKaviraj

http://www.facebook.com/permalink.php?story_fbid=1330116352037&id=1804852296#!/profile.php?id=1685594050

Todd Millions Comment left 20th November 2010 00:12:48

Training indeed is the nub in such systems-perhaps village sized ones with trained operators at first should be a priority,in areas were the new equipment isn't used.

The toilets tied into them-since training is required anyway,perhaps it would be a teachable moment to introduce proper Thedford valve units,that don't waste liters of flush water.

After all anyone capable of learning to operate and monitor the digestor should be fully capable of figuring out how to push the seal valve lever-our witless suburbanoids and their equally dopey country wantabees notwithstanding-wasting so much purified piped in water being of SUCH higher status!

The slurry from these digestors not being used for feild fertilizer is puzzling to me-given the raw sewage too crop land tradition of this area.

As with all countries with population pressures,China surely subsidizes mineral extraction of fertilizers.Perhaps a region by region rota of shifting these monies too proper application of the digestor slurry instead of mineral fertiliser should be tried.

Once the harried farmers can see for themselves that the slurries are better(exspecially over time),this effort can be shifted to other districts.

caloy soriano Comment left 8th April 2011 18:06:14

Very informative,we want more studies, especially the economic leaf,by developing the rural areaswith a component of biogas development for rural needs,pls. advice us for proper website or publication